hydraulic briquetting machine

As a dedicated model of hydraulic briquetting machine to produce sawdust briquette, the GC-HBP120 specializes in processing fined materials from tree branches, twigs, waste wood blocks, rice husk, straw, paperboard and other wood substances and so on.

Consistence of this hydraulic briquette press machine

The GC-HBP120 hydraulic briquette press consists mainly of mechanical system, hydraulic system and electrical system.

This form shows the main data of this machine

| Model | GC-HBP120 |

|---|---|

| Production capacity (Max.) | 120kg/h |

| Main power | 7.5kW |

| Briquette diameter | 70mm |

| Surge bin volume | 0.45m3 |

| Machine weight | 1000kg |

After the work of pulverizer, feedstock will be further manufactured into dried biomass briquette with higher density so that simple storage and convenient transportation can be realized favorably on the one hand, and the product can on the other hand be employed as forage or fuel. In particular, briquette as fuel boasts energy-saving performance and less carbon emissions, also taken as a clean renewable energy of efficiency.

How this hydraulic briquetting machine works

After being pulverized, tree branches, twigs and waste wood blocks will be extruded into briquettes via the hydraulic briquetting machine, with the moisture content of roughly 12%. Specifically, feedstock is loaded into a material bin, conveyed through a screw conveyor to the briquetting cavity, and pressed into blocks in sequence after the work of hydraulic cylinders and the mould. The product, with the forming density of 0.7-1kg/dm3, will be pushed out along with the slideway.

Advantages of this hydraulic briquette press machine

|

1. Different from the conventionally feet-based machine, this model hydraulic briquetting machine sits itself onto a solidly welded steel frame (as the underbed), the latter of which connects with a bin through a support. Besides, a conveyor and its motor and reducer are installed under the bin bottom; |

Screw conveying system |

|

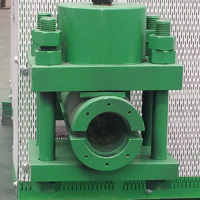

2. The forming system includes three hydraulic cylinders and the mould, with the moulding cavity linked to one end of the conveyor; both the hydraulic power unit and electrical cabinet are situated on the underbed as a whole for the convenient of resettlement. |

Shape forming system |

|

3. A holistic cover is used to keep operators away from hazards. The cover shall not be disassembled during normal running. And feeding observation hole, hydraulic pressure gauge and its switch are all on the cover to facilitate inspection and operation. |

Holistic cover |

|

4. The hydraulic system is composed of hydraulic power unit, motion parts, and connecting parts. In detail, the hydraulic power unit has fuel tank components, oil pump, motor unit and integrated package. Motion parts include all active hydro-cylinders and the connecting parts consist of all linked pipelines. |

Intelligent pressure switch and switch gage |

|

5. The electrical control system, divided into auto and manual control parts, covers cabinet and internal components, including control touch screen, PLC and other components. |

Electric control touch screen |

|

6. Three layer warning lights. in operation, if the green light is on, it means the machine is in normal status. If the yellow light is on, means warning status, then you should see what warning message it is. If the red light is on, means the machine should be stopped. then you should see which part it warns and stop the machine. |

3 layer warning lights |

This machine is an excellent model among those hydraulic briquette machines china made. Its good performance makes it popular and well-liked among briquette machine users all over the world. We are sure its outstanding features will bring you great convenience and considerable profit.