Setting Up Industrial Pellet Plants

Nowadays biomass pellets production is a hot industry because of the popularity of biomass pellets. As a result, some farseeing investors grasp this chance to set up their own industrial pellet plants to make profit.

Biomass pellet plant utilizes industrial pellet mill instead of residential pellet mill. Industrial pellet mills have large capacity as 1-2.5ton/h per set. For larger hourly capacity, several sets of industrial pellet mills can be integrated.

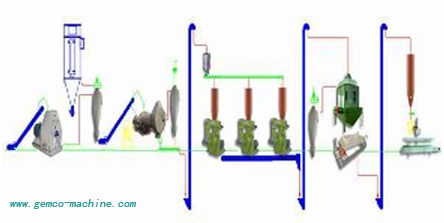

Besides pellet mill, there are also other equipments that form the industrial pellet plant.

Composition of a complete industrial pellet plant

Crusher or hammer millMost of the time, the raw material is not suitable for pelletizing directly, for example: wood chips, timber, logs, straw, stalk, bagasse, palm fiber, coconut shell, etc. In this case, these raw materials shall be crushed into powder. But if your raw material is around 2mm sawdust, you do not need to crush it.

Dryer

The biomass raw materials often have high moisture content (like >20%), but the suitable pelletizing moisture content is 8-18% (depending on raw materials). So you also need to dry the raw material. The dryer with hot air flow can decrease moisture content to required level, which is quite efficient.

Conveyor

This is also an important composition of industrial pellet mill plant sine it can save labor and make the plant more automatic. There are screw conveyor, belt conveyor and bucket conveyor. Usually, the engineers will choose a proper kind of conveyor according to your raw material, budget and other factors.

Industrial pellet mill

It is the soul of the complete plant, since it determines the quality of your biomass pellets. Therefore choosing a good pellet mill is extremely important. Some pellet mills from China are very cheap, but they always have bad quality that cannot be used for long time. Different from them, GEMCO pellet mills have high quality. We have built many pellet plants overseas for our customers and won their recognitions. So if you want high quality pellet mill, just choose GEMCO!

Cooler

It is used to cool the hot pellets and also screen them to get good ones. Those broken pellets and powder can be collected for reproduction.

Pellet packing machine

If you set up industrial pellet plant, you must need to pack the pellets in bags, whether small or large. So the pellet packing machine is also indispensable.

What do you need to prepare for the industrial pellet mill plant?

Before setting up industrial biomass pellet plant, you need to have enough funds and workshop.

The former determines your plant scale and the equipments you can use, while the latter determines the pellet plant design and placement.

*As to the workshop, you’d better build near your raw material, so that you can save a lot of raw material transportation cost. In addition, before setting up industrial pellet plant, you also need to apply 3 phase electricity.

Knowing the composition of complete pellet plants can help you learn more about it, and also know how to choose a professional supplier. And we believe you will make great profit from biomass pellets making.

More professional information, please consult our engineer.