Factors Affecting the Output of Biomass Wood Pellet Machine

The biomass new energy industry is developing rapidly, and wood pellet machines have become more and more familiar to people. There are also many people who reviewed the situation and seized opportunities in this industry, and engaged in the production of biomass wood pellets. However, in actual production, the capacity of the biomass wood pellet machine production line seldom can reach its designed capacity. As a result, the production efficiency is reduced, the manufacturing cost is increased, and the product's market competitiveness is affected.

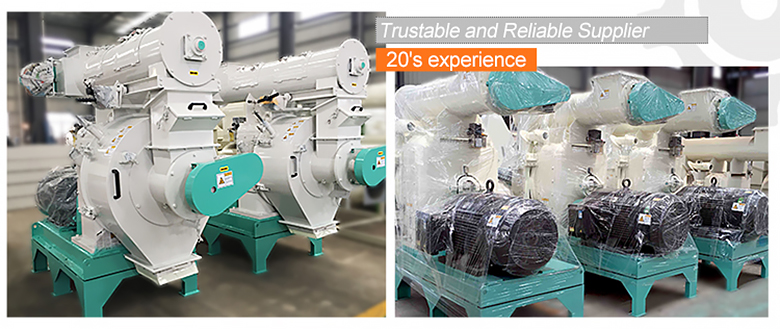

Wood Pellet Machine Manufacturer

Biomass wood pellet machine is a high-energy-consuming production equipment. If the capacity of wood pellet machine cannot be maximized, it will be a great waste of power resources and increase the cost of energy consumption per ton of pellets. Therefore, how to improve the production efficiency of the wood pellet machine is very important. ABC Machinery is an experienced manufacturer and supplier of wood pellet machines. We will patiently discover the reasons for the decrease in the output of biomass wood pellet machines from the details. The following is an analysis of many factors that affect the productivity of the biomass wood pellet machine. If you find any problems in the wood pellet processing and production process, please feel free to contact us, we will give you professional guidance!

Material Factors of Biomass Wood Pellet Machine

First of all, everyone should know that the production requirements of the biomass wood pellet machine are: the raw material is powdery, the pulverization coefficient does not exceed 2/3 of the particle diameter, and the raw material moisture requirement is between 13%-20%. Only when these three production and processing conditions are met at the same time can the solid and perfect wood pellets be produced.

Making Elephant Grass Pellet

-

Material bulk density

Generally speaking, the larger the unit volume weight of the material (that is, the bulk density), the higher the pelletizing output. The raw material of the biomass sawdust pellet machine is wood chips, and in actual production, when wood is collected, some other light substances are often mixed into it, resulting in a decrease in bulk density and a decrease in output.

-

Material moisture

If the moisture content of the material is too high, the quenching and tempering process will be difficult and easily cause the material to slip between the inner wall of the ring die and the pressure roller, resulting in blockage of the ring die hole; if the water content is too low, the bonding ability between the materials is poor and the forming rate will be low.

-

Material size

The smaller the particle size of the material, the higher the production capacity of the biomass sawdust pellet machine, but it will affect the forming rate of the pellets; if the particle size is too large, it will increase the wear of the ring die and the pressure roller, and the energy consumption will increase, and the production efficiency of the biomass sawdust pellet machine will be reduced.

Operating Factors of Biomass Wood Pellet Machine

-

Temper moisture

Before the raw material enters the machine, it can be tested with a humidity measuring instrument to check whether the humidity of the material is within a reasonable granulation range. When the tempering moisture exceeds 18%, the material is easy to slip between the inner wall of the ring die and the pressing roller, and even the pellets cannot be pressed, which reduces the pelletizing output of the biomass wood pellet machine. If the quenched and tempered moisture is lower than 14%, the friction between the material and the machine will be severe, shorten the life of the ring die, and reduce the production efficiency and granulation output at the same time.

-

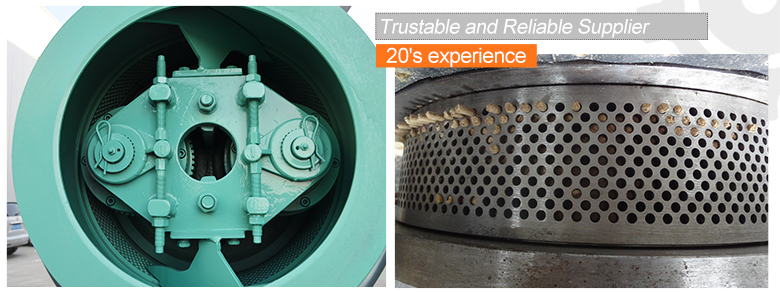

Roller die gap

Roller Dies of Ring Die Pellet Machine

The gap between the pressure roller and the ring die is generally 0.3mm-0.5mm. If the gap between the pressure roller and the ring die is too small, the pressure roller will increase the friction of the ring die and shorten the use time of the ring die. On the contrary, if the gap is too large, the material layer is too thick and unevenly distributed, which will cause difficulty in discharging and reduce the production efficiency and output of the biomass wood pellet machine. At the same time, check the distribution of the raw materials in the ring die. Do not allow the raw materials to run on one side. If a similar situation occurs, the position of the feeding scraper must be adjusted to make the raw materials evenly distributed in the ring die, which can extend the service life of the ring die. , And the granulation process is also smoother.

If you have any operational problems during the production and processing of the biomass wood pellet machine, please contact us and we will give you professional guidance!

Equipment Factors of Biomass Wood Pellet Machine

Choosing the Right Ring Die Compression Ratio

The new ring die has some iron filings and oxides attached to the inner wall of the die hole. Before use, it should be polished to make the inner wall of the die hole smooth, reduce frictional resistance, and increase the output of the biomass wood pellet machine. Moreover, it is necessary to choose the appropriate compression ratio of the ring die of the biomass wood pellet machine. Different materials correspond to the compression ratio of different moulds. The manufacturer can determine the compression ratio when testing the machine. The key problem is that the material and equipment cannot be easily replaced after purchase. If the compression ratio of the ring die is too large, the resistance for the powder to pass through the die hole is large, the pellets are too hard, and the output is low; if the compression ratio of the ring die is too small, the pellets cannot be pressed out, and the production efficiency and output are also low.

Choosing the Right Biomass Wood Pellet Machine

The choice of biomass wood pellet machine equipment is the factor that solves how to increase the output of wood pellet machine. First of all, when purchasing wood pellet machine products, we must conduct in-depth research and analysis on the market and manufacturer cases to find suitable wood pellet machine products. The correct choice of wood pellet machine is the standard fuel, which must meet the requirements of reducing carbon emissions and reducing pollution. In the actual production process, stability is a very important factor, so we have to choose products with a low failure rate. High-quality wood pellets machine have the opportunity to have a high level of production efficiency and output.

Philippine 2TPH Elephant Grass Pellet Production Line

| Raw Material |

Bamboo

|

Manioc waste

|

Chestnut

|

Bits of wood | Log | Palm fruit string |

|---|---|---|---|---|---|---|

| Yield | 1TPH | 1TPH | 2-3TPH | 3TPH | 4TPH | 4-5TPH |

| State |

Ghana

|

Nigeria | Italy | Pakistan | Serbia | Serbia |

The biomass wood pellet machine manufactured by ABC Machinery selects alloy steel ring die processed by world-leading equipment and technology, which has a long service life, smooth grain output, high quality; easy operation, high yield and low labor intensity. If you don't know how to choose a suitable wood pellet machine, welcome to consult us, and we will introduce you to the details of the equipment and the specific parts of the technical improvement.

Elephant Grass Pellet Plant Operation Video