Mobile Small Pellet Plant

With the depletion of mineral energy and increasingly serious environmental pollution, biomass energy has the advantages of renewable and pollution-free, which will be paid more and more attention to. Biomass briquettes and biomass pellets will be more widely used in industrial production and people's daily life, and the market demand will be more extensive. Accordingly, market demand for biomass pellets will be more and more exuberant and the development potential is huge. (Read more: Biomass Briquette Machine >>)

Biomass Pellets Huge Market Potential

Buy High Quality Mobile Pellet Plant

This mobile biomass pellet plant is specially designed for biomass pellet production. It combines the domestic and international advanced pelletizing technology to optimize its performances. It can produce both biomass pellets and animal feed pellets. So, it can process a very wide range of raw materials and can be used in many occasions, like farms, small or medium or large factory, for business or individual uses. (Related Post: Poultry Feed Pellet Mill Plant >>)

- Main Equipment: Hammer mill, cyclone separator, material mixing & storage bin, screw feeder, ZLSP-300B R model pellet machine, water tank, vibrating screen, bucket conveyor, foundation frame and electric cabinet.

- Raw Materials: Sawdust, twigs, waste wood, straw, peanut shell and other biomass raw materials or animal feed raw materials. (Read more: Commercial Wood Pellet Mill >>)

- Applications: Civil heating and life energy, biomass industrial boiler; small, medium or large sized livestock, poultry farms, or aquaculture, or animal food feed processing plant.

- Main Market: Chile, Greece, Italy, Latvia, Namibia, Portugal, Rumania (Romania), Spain, Latvia, Ukraine, etc..

GEMCO Multi-functional Biomass Pellet Plant Structure

GEMCO Mobile Biomass Pellet Plant Technical Specifications

| Model | MPL300 |

|---|---|

| Diameter of Pellets | 6~12mm |

| Pellet Density | 1.1-1.3t/m3 |

| Moisture Content | ≤8% |

| Overall Size (L*W*H) | 3500*1960*3500mm |

Small Mobile Biomass Pellet Mill Working Video

Buy High Quality Mobile Pellet Plant to Make Biomass Wood Pellets and Animal Feed Pellets: Hot Sale Mobile Biomass Pellet Plant Offered by Biomass Pellet Machine Manufacturer or Supplier, Guide on Process of Biomass Pellets and Animal Feed Pellets Production and How to Start Pelletizing Business with Limited Cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

GEMCO Small Mobile Biomass Pellet Plant Advantages

This biomass pelletizing plant has a significant feature in lowering the maximum height of the complete plant, which makes encasement and shipment much easier.

- Crushing System

This biomass pellet mill factory adopts high-carbon alloy steel blades and a high-speed crushing system to ensure stable performance, durability and high efficiency. In order to ensure safe and user-friendly operation, there are two safety locks on both sides of the shell. And, the position switch is installed on the right side of the shell beside the safety lock. In addition, a fence is designed to prevent the over-sized material feeding into the crushing chamber. And, four strong magnetic separating blocks are installed at the sliding plate of the feeding hopper.

-

Pneumatic Conveying Unit

This unit includes one 2.2kw air blower, wind pipeline and cyclone separator. It will transport the crushed material into bin for mixing and storage. It's connected with vibrating screen and bucket conveyor with semitransparent soft pipes to cool the pellets, and collect the powder and dust.

- Material Mixing and Storage Bin

It's with 1m3 volume, its shell is made of 2.5 mm steel plate. There are two portholes on both sides for monitoring and observation. The highest material level for this bin is at 800mm from the bottom.

- Screw Conveyor

It's 112mm in diameter, 1023 mm long. It is to feed the mixed material into the pellet mill, and is driven by frequency conversion speed controlled motor, 0.18 KW, frequency conversion range is 30~60 Hz. By using frequency converter, its feed-in capacity can be also adjusted consistently and stably, which assures the machine sufficient material supply and avoids surplus feedstock, so the pellet machine can work under perfect condition.

- Pelletizing Section - Small Pellet Mill Machine

| Model | ZLSP300R | ZLSP400R |

|---|---|---|

| Wood Pellet Capacity | 250-350kg/h | 350-450kg/h |

| Packing Size (mm) | 1350*750*1400 | 1400*800*1450 |

| Motor Power (kw) | 22 | 30 |

| N.W./G.W. (kg) | 540/575 | 770/810 |

| Diameter of pellets (mm) | 6-12 | |

| Material of flat die &roller | Alloy steel | |

| Service life of flat die & roller | Min. 800 hours | |

Above is the technical parameters of the flat die pellet machine that is equipped in this mobile pellet plant. To set up complete pellet plant, we also provide ring die wood pellet mill and also offer customized plan on factory design, machine selections, equipment installation and onsite commissioning service.

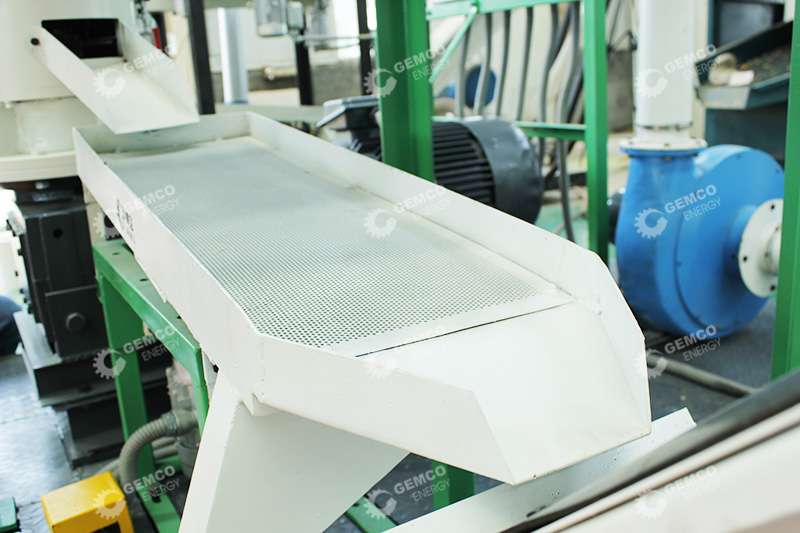

- Vibrating Sieve

This system consists of one 0.75kw motor, one reduction gearbox, vibrating sieve, soft pipeline for powder & dust collecting, and supporting steel structure. It is with multifunction, capable of:

- Remove & Collecting the dust and powder -- Dust and powder will appear during production, they will go through the sieve and be collected and removed by soft pipeline which under the sieve. This sieve is added to further improve the cleanliness of the work environment.

- Cool the pellets simultaneously, to reduce the temperature and moisture content of newly produced pellets to match the requirements.

- Scraper Conveyor

The size for single section is 2436*437*484 mm. The length and height of this conveyor can be extended by adding and connecting one extra section. There are five positioning joints at the end of the conveyor, you can adjust the height and angle of the conveyor easily. Two φ100mm soft pipes is connect to cool the pellets.

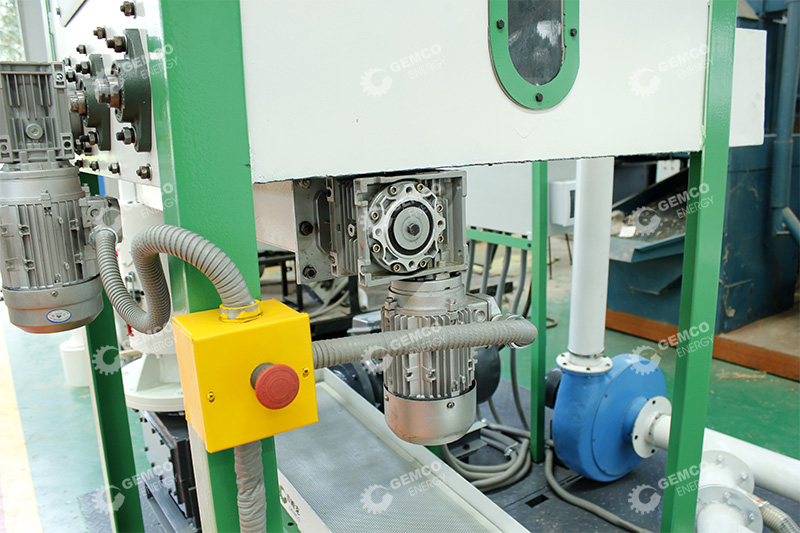

- Electronic Control System

Compact control cabinet is designed with dust prevention. It adopts high quality Schneider Electric Brand Electric Components Control Board for Frequency Conversion Speed Controlled Motors, with dust prevention.

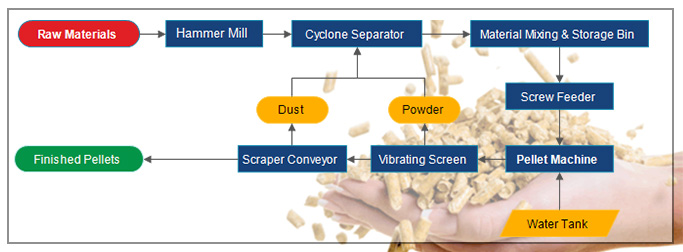

How GEMCO Mobile Biomass Pellet Plant Works?

Production Process of Mobile Pellet Mill Machine

Above is the general flow chart of this mobile pellet mill plant. If there are any questions about the pellet production process, please contact us, our technical engineers will explain it and offers more details about how to make the pellets by using our multi-functional mobile pellet mill plant!

This newly developed mobile biomass pellet plant has been utilized by several of our customers, and has got positive feedbacks of its high technology, good performance and output. With years of expertise and experience, GEMCO manufactures this mobile biomass pellet plant to meet high-end pellet production demand. If you are interested in this pellet plant or have any questions, please do consult us for details!