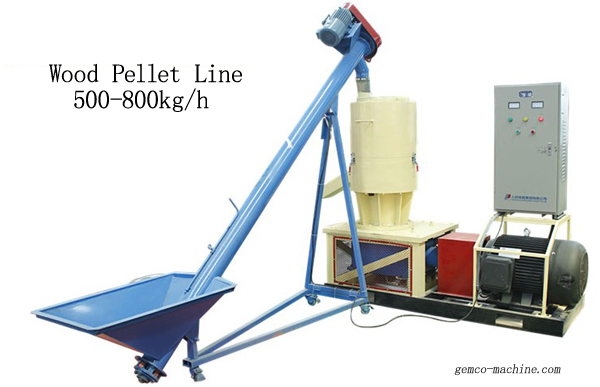

ZLSP R-Type 550B Pellet Mill

500-800kg/h wood pellet line is newly designed for pellet production. It has a high efficiency not only on wood pellet making, also on animal feed pellets making. It's suitable for small scale pellet production.

Under heavy-duty working condition, it’s enjoying a wide application range from sawdust, agro-waste to some chemical industrial material and pharmaceutical material.

CE certificated equipment quality guarantees a stable operation, satisfying customers with reliable requirements.

The 500-800kg/h wood pellet line combined by two parts, one is the ZLSP R-Type 550B pellet mill , the other is movable screw feeder.

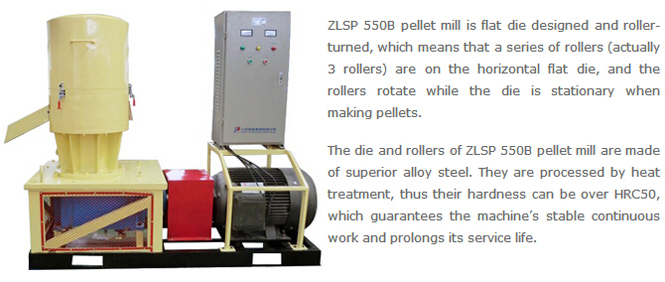

ZLSP-R 550B Pellet Mill

| Model | Power(kW) | Capacity(kg/h) | Weight(kg) | Dimension(mm) | |

|---|---|---|---|---|---|

| ZLSP-R 550B Pellet Mill | 55 | Wood | Feed | 1900 | 2300x750x1850 |

| 500-800 | 800-1100 | ||||

| Remark: the capacity is basis on saw dust as raw material under hundred times testing. | |||||

Features of ZLSP-R 550B Pellet Mill

- Equipped with updated electric motor with ample power, it is more suitable for hard material processing, such as beach, aburagi and oak etc, which causes big resistance, high current and hard to transform, requiring higher structure strength. Meanwhile the equipment processes loose and soft material much easier, such as animal feed, pine, straw etc. The service life is extended.

-

The equipment adopts Germany Flender technology B series heavy-duty reducer, which is able to bear heavy load. At the same time, match the exclusive compulsive lubricating pump realized auto-lubrication under running, improving the reliability of reducer.

- Electric motor adopts SELF-COUPLE STARTER with big starting torque and stable starting. It is superior to star triangle starter, reducing the impact on electric grid efficiently when it starts, therefore, not only protects electric motor but also improves the equipment performance.

-

Aimed at materials with big volume weight and good fluidity, multi-roller compressing system is designed to improve pellet making efficiency and equipment performance.

-

The key parts, roller and die are made of high strength alloy which is processed by multi-times prepare heat treatments and final heat treatment. The hardness reaches to HRC52-63 guaranteed the strength and extended life time. It can running about 600 hours when process sawdust pellet while it is about 800-1000 hours with animal feed pellet.

- Through changing the traditional tightening nut to special nut, solving the problems that the pressing force changes because of the traditional screw nut loosing due to the equipment vibration during operation. Thereby rollers run more smoothly, and can get more & high quality pellet.

- Even though the equipment capacity is improved a lot, the operation is similar with that of small pellet mills, easy to use & maintenance. Besides, variable frequency screw feeder can be used to reduce labor intensity.

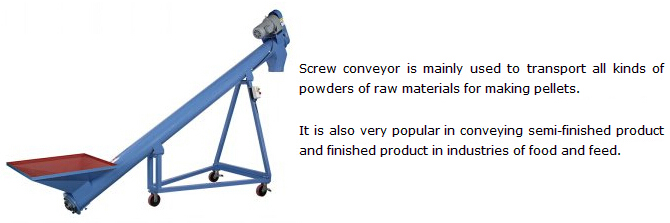

Movable Screw Feeder

We suggest you to match this feeder when you using the big capacity pellet mill to guarantee stable feeding.

Model:GMSLLX75D

Power:1.5KW

Capacity:1500KG/H (sawdust)

Conveying length:2.5M or so

Working temperature range : -20°~40°C

Conveying material temperature range : -20°~200°C

Features:

- Equipped with frequency transformer, it is suitable for different models of pellet mills since the conveying capacity can be adjusted.

- Installed wheels, so you can move it to other place easily when necessary.

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!