GEMCO Pellet Machine Flat Die and Ring Die

GEMCO pellet machine has become a world famous brand biomass pellet machine nowadays because of its reliable quality and good after sales service.

As a leading pellet machine manufacturer, GEMCO Energy keeps developing itself in bioenergy field. GEMCO now has a technology research and development center with over 25 R&D staff with doctor or master’s degrees devoting into biomass pellet machines. Over years of researching, improving, learning and testing, GEMCO has made its biomass pellet machines ranking top in biomass energy machinery field.

Now all GEMCO pellet machines are CE, BV, and ISO approved, which also can meet EU standard.

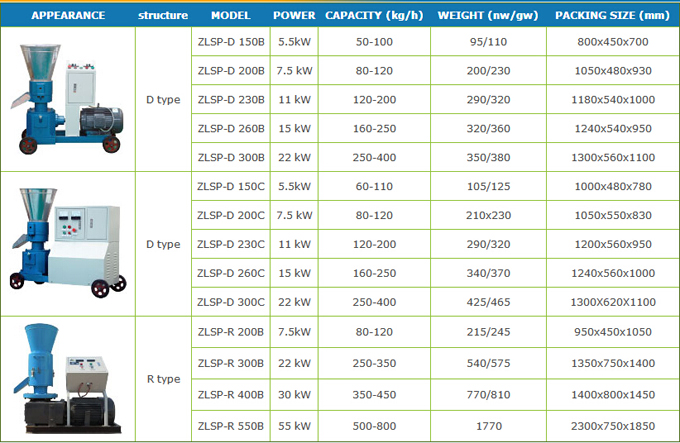

GEMCO pellet machine flat die

The flat die pellet machines manufactured by GEMCO Energy have excellent quality.

- The transmission device adopts reduction gears instead of bevel gear that is adopted by many other manufacturers. The reduction gears have much lower noise, longer service life (300-500h) and can rotate both forward and reverse; but its price is higher. While the bevel gear used by other manufacturers costs less but it cannot rotate reversely for long time.

- Main parts flat die and main shaft are made from 40Cr instead of 45# steel. The 40Cr contains more Cr, which makes the main parts more wear-resisting and the hardness can reach 60HRc. While the 45# steel has lower hardness and wear-resistance.

- The roller, flat die, main shaft and roller shaft are processed by vacuum heat treatment instead of cemented quenching to be harder, wear-resisting and have longer service life. The vacuum heat treatment does not damage their surface and does not deform them, but the production cost is higher. While the cemented quenching can deform these parts.

- The GEMCO pellet machine can produce 10-20kg/h more than those machines from other factories. For example, the ZLSP200B D-type can produce 80-120kg/h wood pellets, while the same model made by others produces 70-110kg/h.

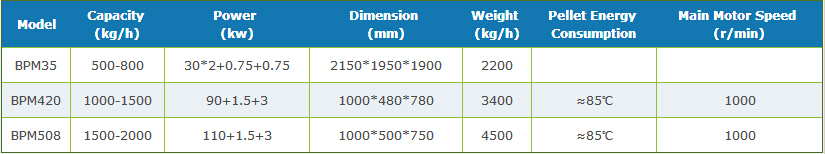

GEMCO pellet machine ring die

ring die pellet machines

The ring die pellet machine manufactured by GEMCO Energy takes the largest Chinese market share and also large proportion in South East Asia.

- GEMCO ring die pellet machines are suitable for various kinds of biomass raw materials, such as dry sawdust, wet sawdust, logs, bamboo powder, wet bamboo shavings, canola, corn stalk, and cotton bar, straw, rice husk, bagasse, palm pomace and MDF powder. The annual productivity can be 150,000ton.

- The ring die pellet machine can run 24hours continuously and be lubricated without stop. The new lubrication device takes the advantage of good flowing nature of engine oil to successfully and quickly deliver the oil into the spindle oil filter pipe, making the shaft balls fully access oil. Besides, this lubrication system does not pollute the pellet machine engine oil. The flowing oil is visible to operators. This automatic lubrication system can improve pellet machine working efficiency and decrease labor working intensity.

- GEMCO ring die pellet machine advanced gear transmission technology which is also applied by CPM. Compared to belt transmission, its efficiency is greatly increased, while the weariness is decreased.

- The ring die is a patented technology, which is anti-cracking, has high productivity and can be used to work as long as 800 hours.

No matter you choose flat die or ring die GEMCO pellet machine, you will be satisfied with both the machine performance and our wholehearted service. Do feel free to contact us at any time!