ZLSP R-Type 200B Pellet Mill

There is a wide variety of biomass fuel pellets on the market. And, biomass pellets are mainly made from cork wood, hardwood and blend wood (80% hardwood and 20% cork wood).

Cork Wood and Hardwood Pellets

Although most of the biomass pellet machine on the market now can process both cork and hardwood, cork and hardwood are different on density and moisture content, so adopting the professional pellet mill that is designed for hardwood would achieve great pelletizing effect.

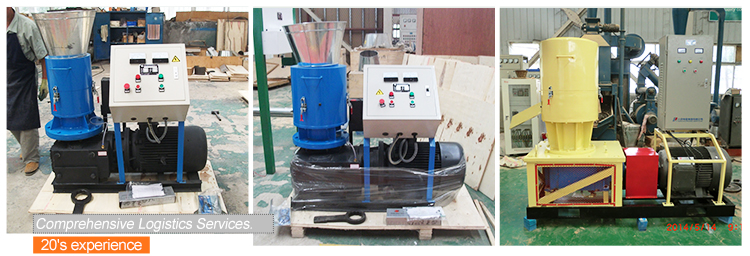

ZLSP R-type 200B Pellet Mill at Factory Price

ZLSP R-type 200B pellet mill is a hot sale small wood pellet making machine manufactured by GEMCO. With a rotating roller and fixed pressing die, this model is excellent in making hardwood pellets. For softwood pellet processing, please choose D-type flat die pellet mill.

| Model | Capacity | Power | Weight (NW/GW) | Outside Dimension | Delivery Time |

|---|---|---|---|---|---|

| ZLSP R-Type 200B | 80-120kg/h | 7.5KW | 215/245kg | 950*450*1050mm | 7-12 working days |

Please Note: GEMCO provides different capacity pellet machine to meet different needs. For more technical parameters, please seed our product catalogue. If you are interested in, please contact us to get the price list!

How the Roller of GEMCO Wood Pellet Mill Rotates?

The rotating roller of GEMCO pellet mill can generate great pressure, and the pressure is put upon the powdery materials of beech, birch, lime, maple, oak, elm, etc. and then solid wood pellets are extruded through the die holes and produced with smooth or even shiny surface.

Rotating Roller of GEMCO R-type Pellet Mill

Reasons to Choose GEMCO R type Pellet Mill

Gemco Wood Pellet Mill for Sale

- Equipped with newly spike wheel and ensuring the capacity

- Increasing the eyelet quantity in disc from original 28 to 70

- High efficiency of all the eyelets by using the roller with a cross wheel in our machine

- Saving 1-2 workers by adopting automatic materials discharge set

- Prolonging the shaft bearing life by installing the circulation lubrication system

- Avoiding materials into body and lengthen bearing life by improving seal technology

How to Use GEMCO Wood Pellet Mill?

For wood pellets making, you need not only wood pellet mill, but also other auxiliary equipment, crusher and conveyor. If you have sufficient budget, a dryer and a cooler are also necessary to start a small wood pellet plant. In addition, to feed the raw material into wood pellet mill, a conveyor is needed for saving labor.

Raw Materials — Crushing — Drying — Pelletizing — Cooling — Packing

GEMCO R-type 200B Wood Pellet Mill

GEMCO Pellet Mill - buy high quality r-type pellet mill for biomass pellets making: Hot sale R-type pellet mill offered by biomass pellet mill manufacturer or supplier, guide on process of pellets production and how to start pellets making business with limited cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.